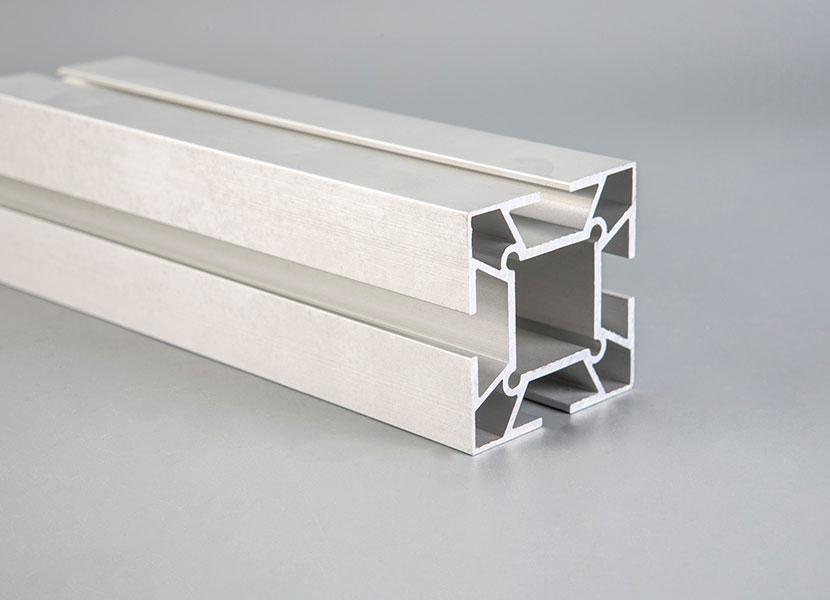

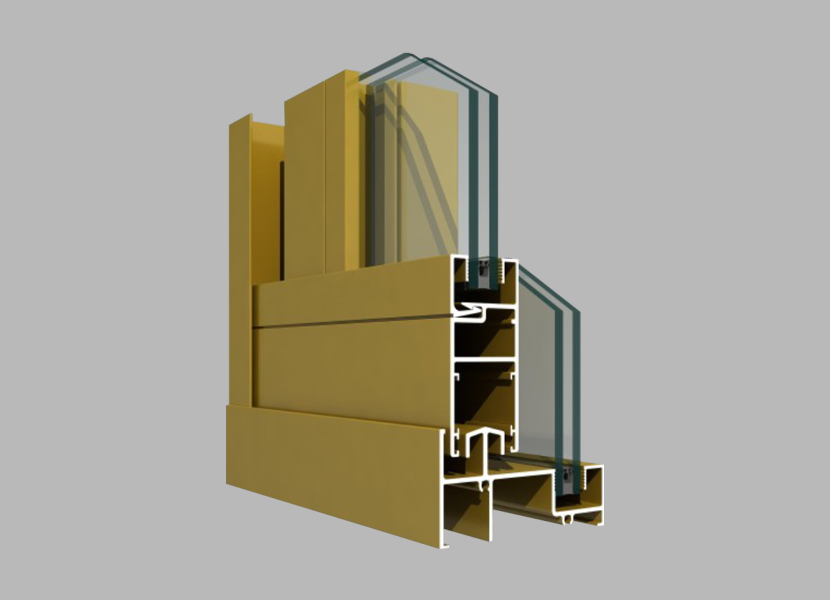

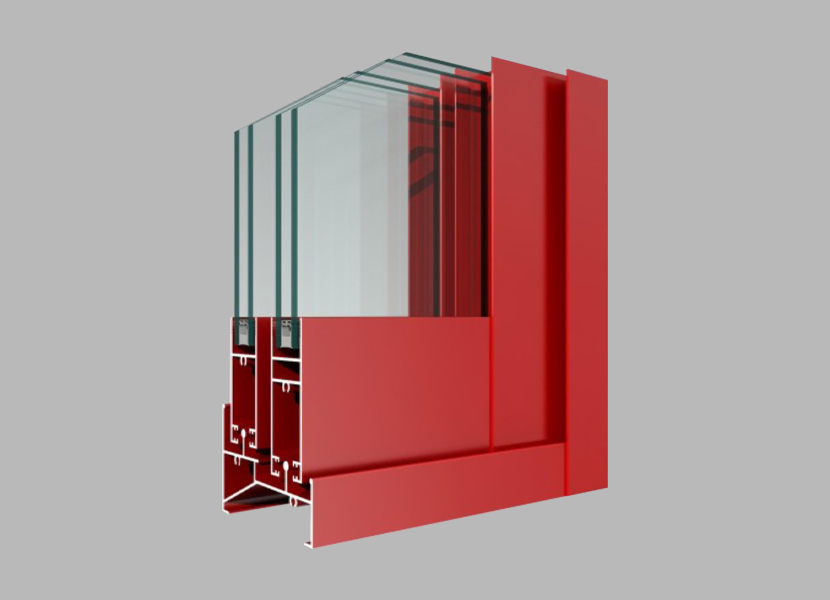

The field of industrial aluminum profiles is nothing more than three important sectors: aluminum profile production, aluminum profile processing, and aluminum profile frame installation. Among them, aluminum profile processing is a plate with relatively large elasticity. Because aluminum profiles can be processed into various frames, and the processing methods are generally cutting, drilling, and tapping. So can all aluminum profiles be processed? What problems should we pay attention to when processing aluminum profiles? Let me answer your questions below!

First of all, a concept should be emphasized here: not all aluminum profiles can be processed! The reason for this is that the aluminum profiles produced by the aluminum profile manufacturers are not necessarily all qualified, and the wall thicknesses meet the processing requirements. For example, when the wall thickness is too thin, drilling, tapping, etc. cannot be completed. For another example, the produced aluminum profiles are not qualified products, and there are scratches or defects on the surface. These aluminum profiles are equivalent to waste aluminum materials and cannot enter the market. Therefore, the first thing to pay attention to when processing aluminum profiles is whether the aluminum profiles to be processed are qualified products.

Secondly, we must pay attention to personal safety and product safety during the processing of aluminum profiles. Why do you say this? Because the machines used in profile processing all require some machine operations. If you do not pay attention to the operation, it is easy to cut your hands and cause personal injury. In addition, if you are not careful, it is easy to cut the wrong size, or the tapping will appear in the wrong position, or cause other damage to the profile, resulting in the generation of waste profiles.

English

English 简体中文

简体中文 España

España