The titanium-plating process for aluminum profiles belongs to the coating technology. It adds pre-plating and electroplating process steps on the basis of the conventional titanium-plating process. The aluminum profile process is to place the activated plated parts in an aqueous solution of salt and hydrochloric acid for chemical treatment.The components of the plating solution in the electroplating process include nickel sulfate, nickel chloride, boric acid, sodium lauryl sulfate, saccharin, and brightener.

This process has the advantages of simplicity, practicality, and good effect. The hardness of the film layer is HV≈1500, and it is 150 times more wear-resistant than plated with 22K gold under the same conditions.The density of aluminum profiles is only 2.7g/cm3, which is about 1/3 of the density of steel, copper or brass (7.83g/cm3, 8.93g/cm3, respectively). Aluminum exhibits excellent corrosion resistance under most environmental conditions, including in air, water (or brine), petrochemicals, and many chemical systems. The machinability of aluminum profiles is excellent.

In various wrought and cast aluminum alloys, and in the various states in which these alloys are produced, the machining characteristics vary considerably, which requires special machine tools or techniques.It can be divided into 1024, 2011, 6063, 6061, 6082, 7075 and other alloy grades of aluminum profiles. Among them, 6 series are more common. The difference between different grades is that the ratio of various metal components is different.

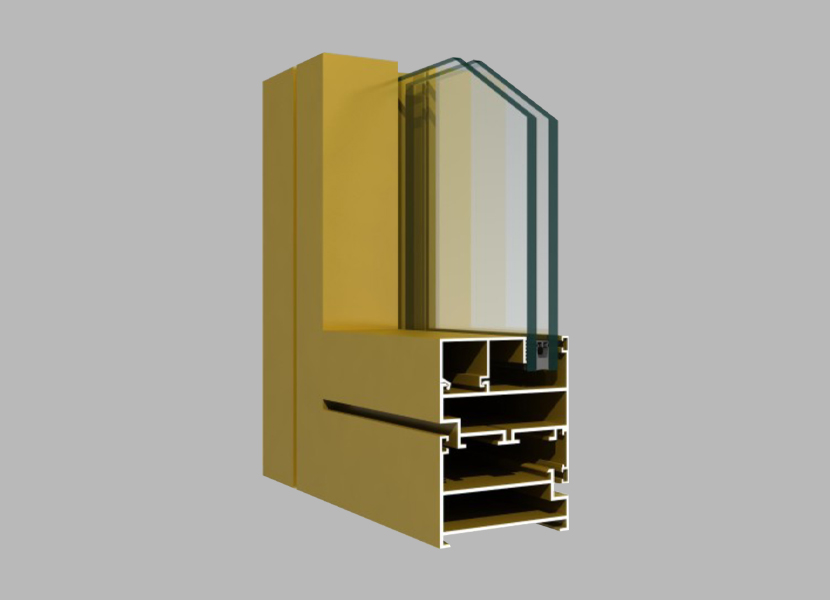

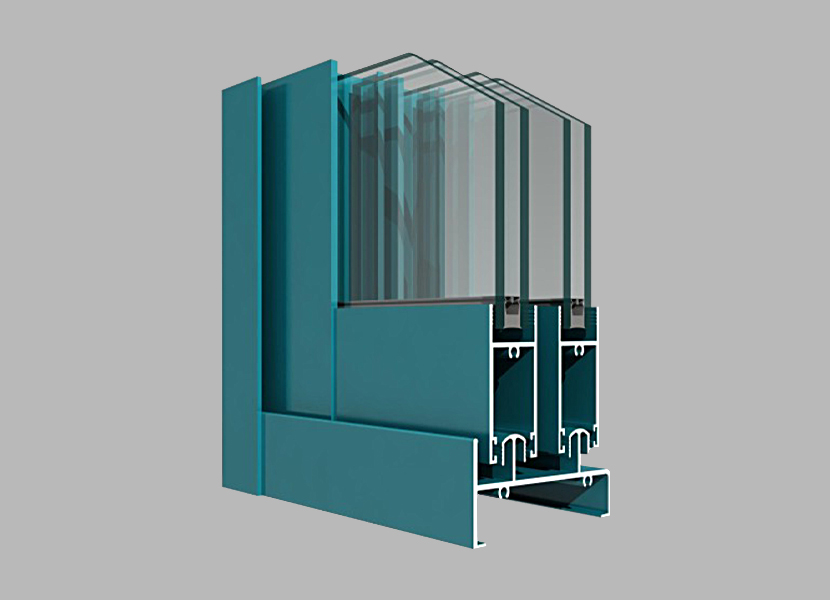

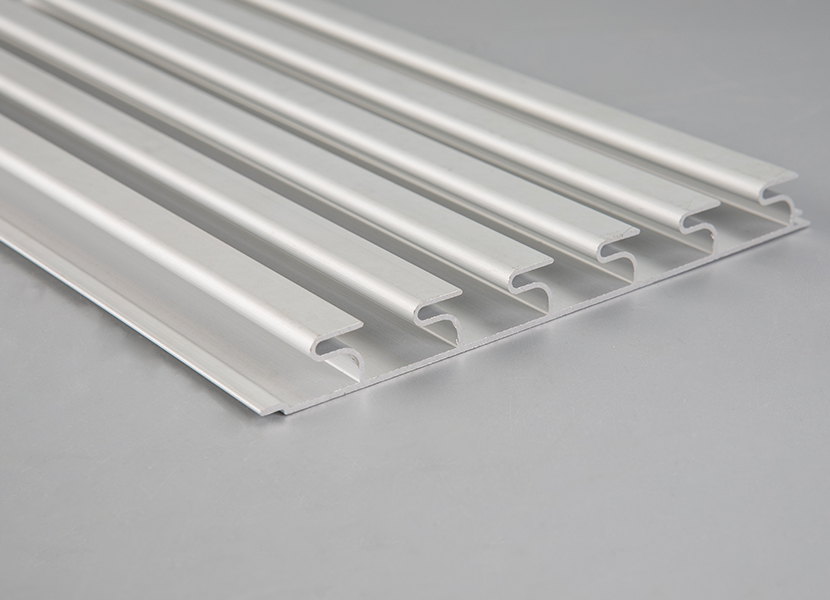

Except for the aluminium profile commonly used doors and windows aluminum profiles Such as 60 series, 70 series, 80 series, 90 series, curtain wall series and other architectural aluminum profiles, there is no clear model distinction for industrial aluminum profiles, and most production plants are processed according to the actual drawings of customers.Extrusion is a means of forming profiles. First, a mold is designed and manufactured according to the section of the profile product, and the heated round cast rod is extruded from the mold by an extruder. The commonly used grade 6063 alloy is also used in extrusion. The air-cooled quenching process and the subsequent artificial aging process are used to complete the heat treatment strengthening. Different grades of heat-treatable strengthening alloys have different heat treatment systems.

English

English 简体中文

简体中文 España

España