Aluminum is one of the most widely used metals in manufacturing today. Aluminium is used in many industries to produce products in an almost unlimited number of shapes for an almost unlimited number of uses. With such a multi-functionality, it is not surprising that there are several different manufacturing methods for the production of aluminum products. The two most commonly used processes for aluminum forming include extrusion and drawing. When comparing the two, there are some major differences.

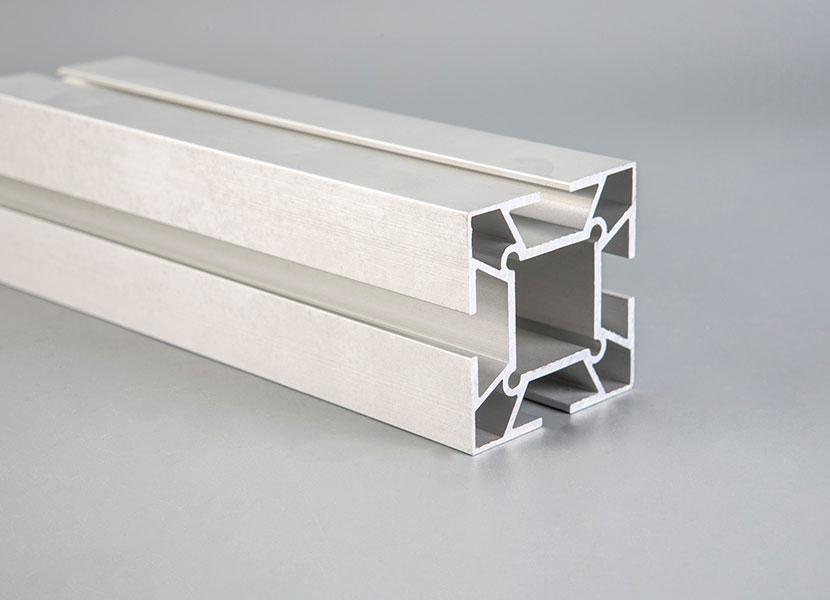

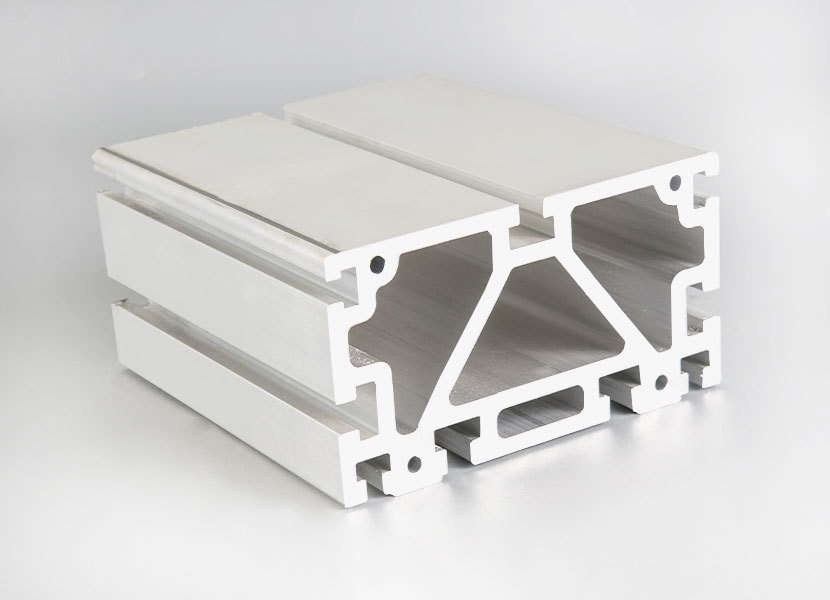

Aluminum extrusion process

The difference between extruded aluminum and stretched aluminum is that the metal is first heated to a very high temperature until it is soft and malleable but not liquid to form a molded shape. After the aluminum is heated, it is then forced or pushed through the mold. The product coming out from the other end will be molded through a mold and formed into the desired final product. In order to visualize the extrusion process, it can help to describe a tube of toothpaste. In this case, the toothpaste is shaped by a circular opening through which the toothpaste is pushed. After the aluminum is extruded, it will begin to cool and harden. As it hardens, the final product becomes strong and durable and will maintain the desired shape.

Aluminum drawn process

The process of drawing aluminum is carried out by pulling or pulling aluminum into the mold cavity, during which the aluminum undergoes so-called plastic deformation. When aluminum is stretched to obtain the desired shape, plastic deformation occurs. When stretching aluminum, you must pay close attention to the flexibility and elasticity of the metal. Stretching too much, it will become fragile and fragile. Drawn aluminum is most commonly used to make products, including pots, cans, tubes, and other round objects.

The difference between drawn aluminum and extruded aluminum

Although both processes can be used to create similar finished products, there are some differences between the two. These differences include:

cost. Generally, the extrusion process tends to be cheaper than drawn aluminum. This is because cold drawn aluminum usually requires a lot of tools and materials to complete.

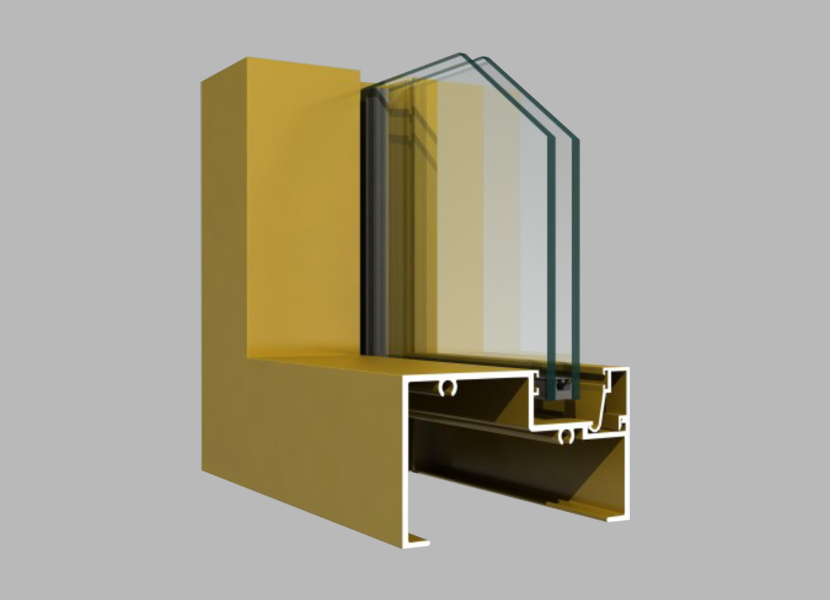

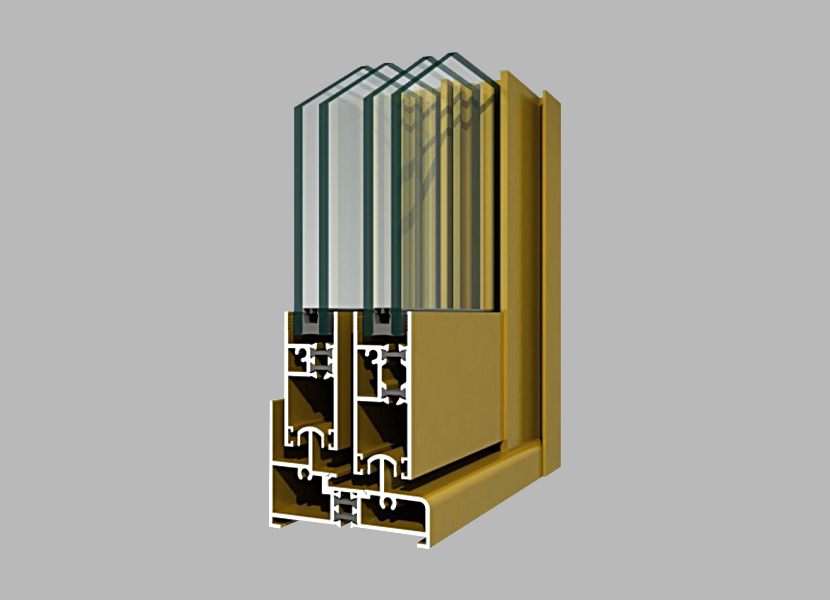

The product has been created. Extrusion and stretching processes are commonly used to produce different types of products. For example, extruded aluminum can be used to make pipes, doors, window frames, brackets, and railings. Except for products such as cans and cans, drawn aluminum will similarly be used to make pipes.

English

English 简体中文

简体中文 España

España