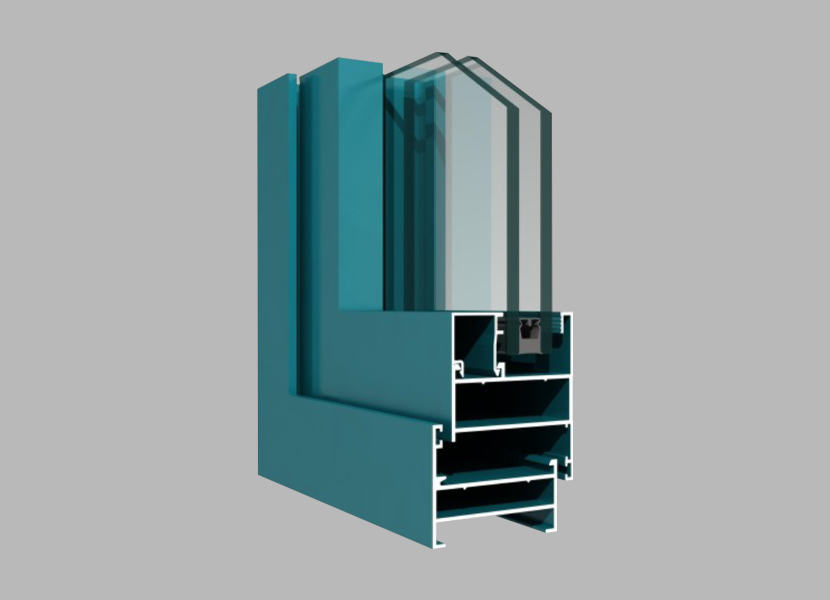

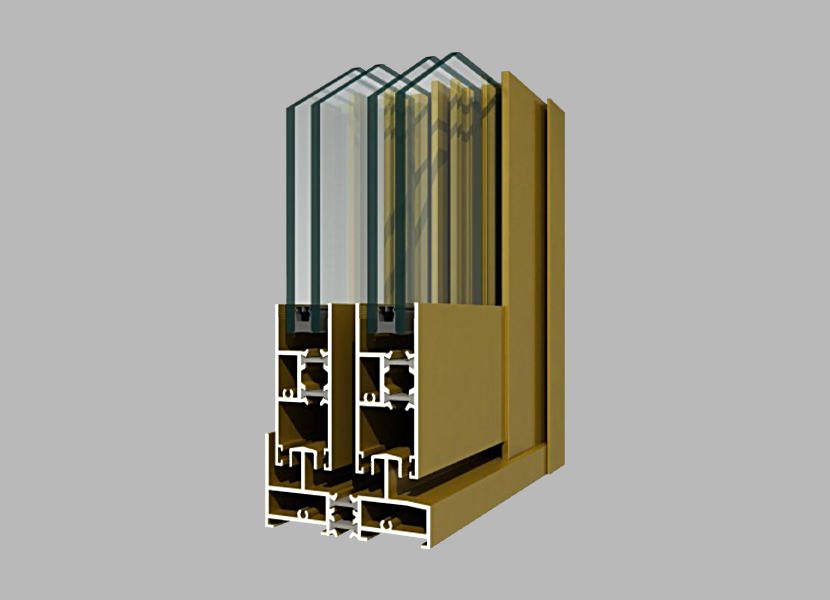

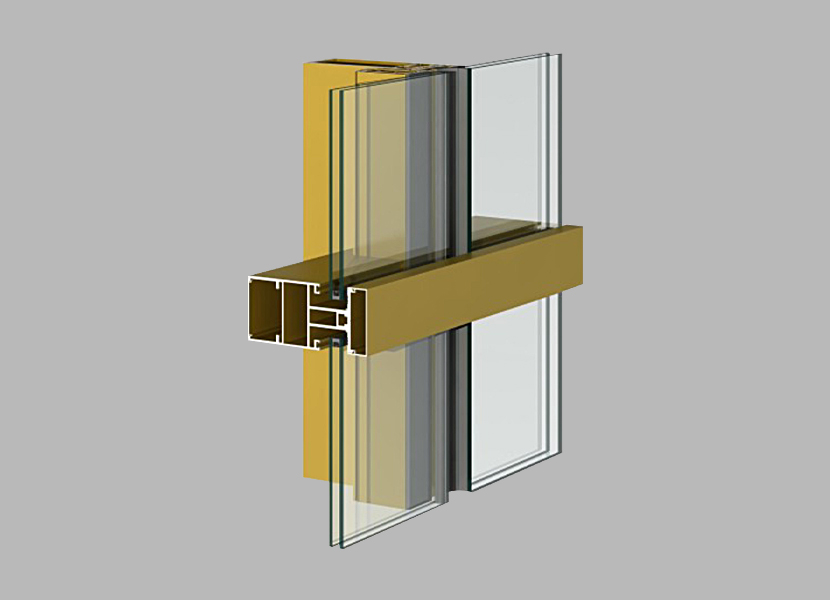

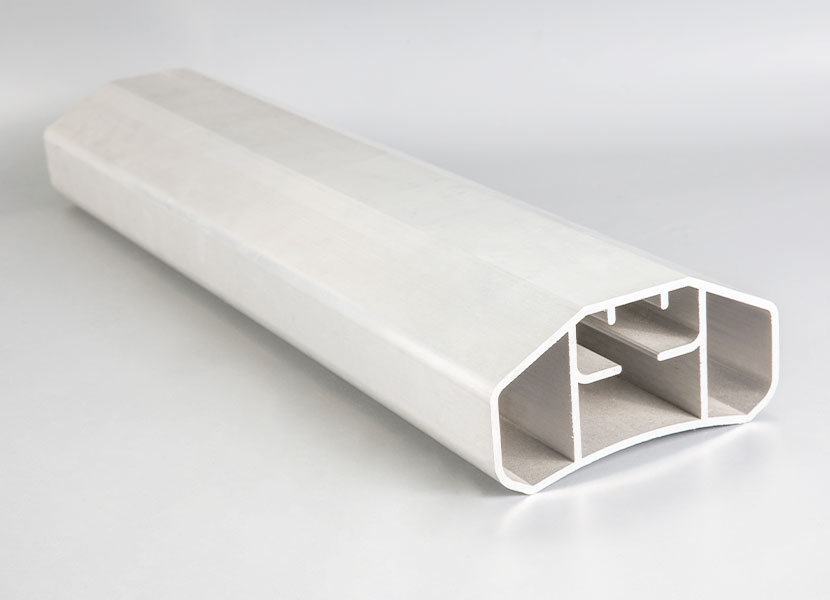

Aluminum extrusion profile is a very common non-ferrous metal material in processing, and its application range is very wide. Before aluminum is used, it is usually processed in various ways to facilitate its use. Extrusion is a molding process of aluminum, that is, after aluminum ingots and other raw materials are melted in a furnace, they are extruded into a mold and flowed out to form. It can also extrude various profiles with different cross-sections.

Extruded aluminum profiles are suitable for the production of long and straight semi-precision products such as tubes, rods, wires, profiles, bars, and angles. The extruded aluminum profile can improve the deformability of the metal. During the extrusion process, the metal in the deformation zone is in a state of three-dimensional compressive stress, which can give full play to the plasticity of the metal and obtain a large amount of deformation. For example, the extrusion ratio of pure aluminum can reach 500.

The extruded aluminum profile has great flexibility in production. By changing molds, products of different shapes and sizes can be produced on the same equipment. It is suitable for the production of multi-variety, multi-specification, and small batch products. Compared with the production of pipe profiles by the rolling method, the process flow is short and simple, and the equipment investment is less.

The structure and performance of extruded aluminum products are uneven. Due to the uneven metal flow during extrusion, the surface layer and center, head and tail of the product are deformed unevenly, resulting in the formation of coarse crystal rings on the surface of the product after heat treatment. Moreover, its production efficiency is low, and the conventional extrusion method cannot achieve continuous extrusion. The Comform continuous extruder developed in recent years can achieve continuous extrusion, but it can only extrude pure aluminum and soft aluminum alloys. The waste produced when extruding aluminum profiles is lost, and each extrusion has a surplus. Cut the head and tail, up to 10% of the weight of the ingot.

English

English 简体中文

简体中文 España

España