In our daily consumption, I believe that many people believe that the higher the price of aluminum alloy doors and windows, the better, and the thicker the material, the better...Because the more materials consumed, the higher the price will be, and the quality will naturally be unnecessary. NS. So, is this view correct?

The thickness of aluminum alloy door and window profiles is not selected according to the standard wall thickness, but is selected according to the door and window opening size, wind pressure value, and the designed air tightness and water tightness of the doors and windows. In the case of ensuring product quality, performance, environmental protection and other requirements, it is not that the thicker the wall thickness of the door and window profiles, the better the product quality.

The quality of aluminum alloy doors and windows should start from the following points

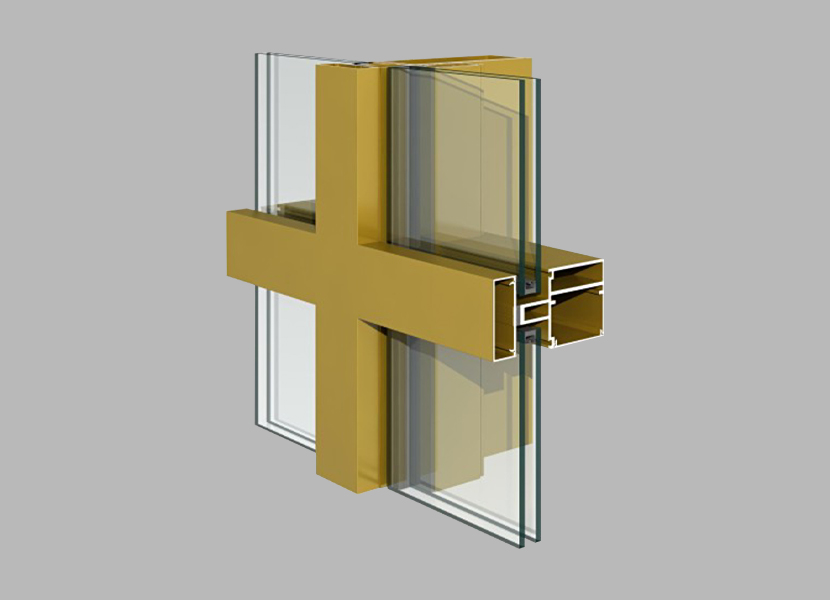

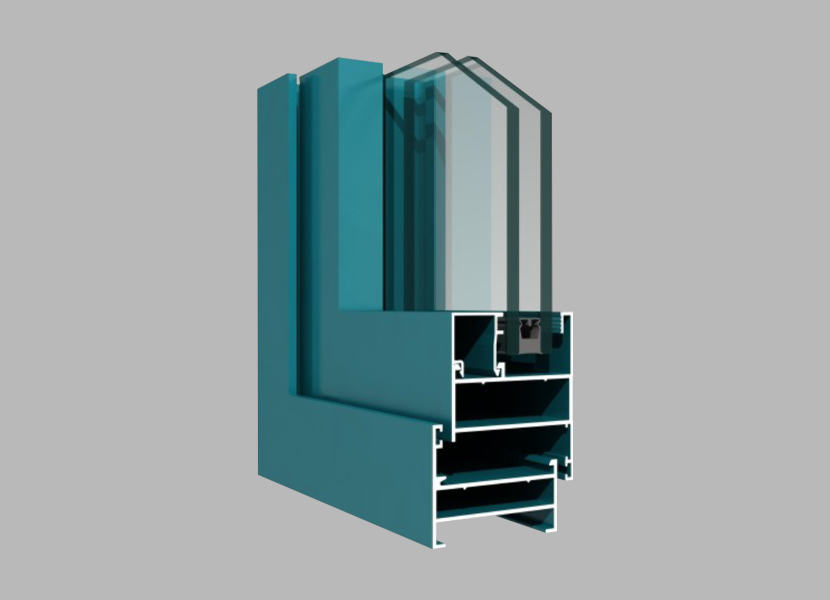

1. Whether the structural design of aluminum alloy profile is reasonable.

2. Whether the air tightness and water tightness of doors and windows meet the standards.

3. What is the configuration of the hardware, glass and accessories of the doors and windows?

Features of aluminum alloy doors and windows

1. Raw materials: aluminum

The aluminum used for good aluminum alloy doors and windows has a smooth and shiny surface, without aluminum chips, burrs, etc., and its strength, thickness (≥1.4mm), and oxide film (≥10 microns) must meet national standards.

2. Raw materials, hardware accessories

The quality of tops, hinges, door handles, locks, pulleys and other hardware accessories is the key to ensuring the service life of aluminum alloy doors and windows. Use stainless steel hardware, bright color, no rust, scratches, etc., it is important to use reliable brand hardware, big brand hardware and profiles will be engraved with brand LOGO.

3. Auxiliary accessories

Sealing strips and wool strips are important parts to ensure aluminum alloy doors and windows, especially hollow doors. The sealing strip has sufficient tensile strength, good elasticity, good temperature resistance and aging resistance, and the cross-sectional structure size should match the aluminum door profile. The top needs to have good sealing performance, good waterproof performance, and dense dustproof.

4. Raw material glass

Compared with ordinary glass, tempered glass is obviously a better choice. It has strong impact resistance and is not easily broken. Even if it is broken, it will shatter in the form of particles without acute angles, which greatly reduces the harm to the human body. At the same time, it has good sound insulation and heat insulation effect.

5. Process and performance

Good aluminum alloy doors and windows have fine processing, smooth tangent, precise angle, no obvious gaps in the splicing process, good sealing performance, and smooth opening and closing. If the processing is unqualified, there will be sealing problems, not only leakage of wind and rain, but also under the action of strong wind and external force, the glass is prone to bursting and falling off. Therefore, it is not to say that the thicker the single aluminum alloy profile is, every auxiliary accessory and every step of the production process cannot be ignored.

English

English 简体中文

简体中文 España

España