Introduction to Thermal Break Aluminium Profiles: Design, Manufacturing, and Benefits

Thermal break aluminium profiles are an essential component of modern building construction. They provide an efficient thermal barrier that minimizes heat transfer and enhances energy efficiency. In this article, we will explore the design, manufacturing, and benefits of thermal break aluminium profiles.

Design of Thermal Break Aluminium Profiles

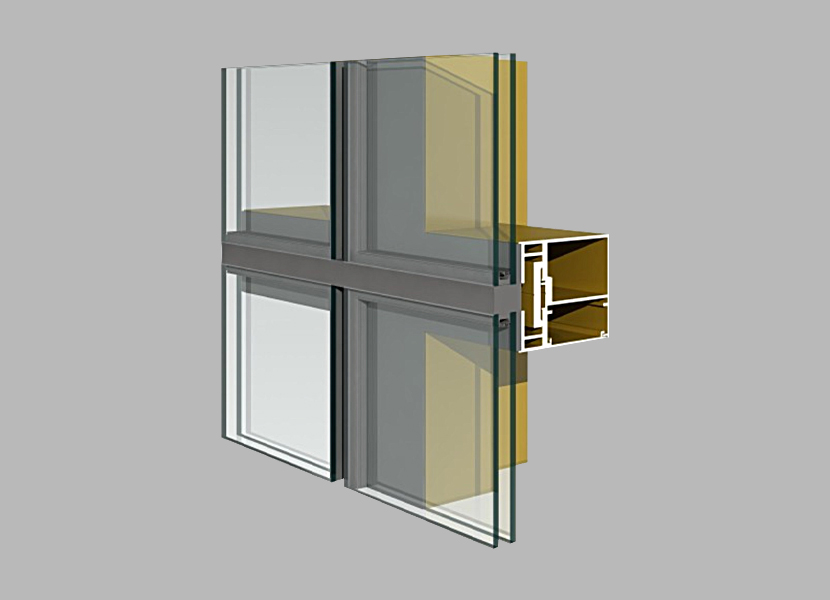

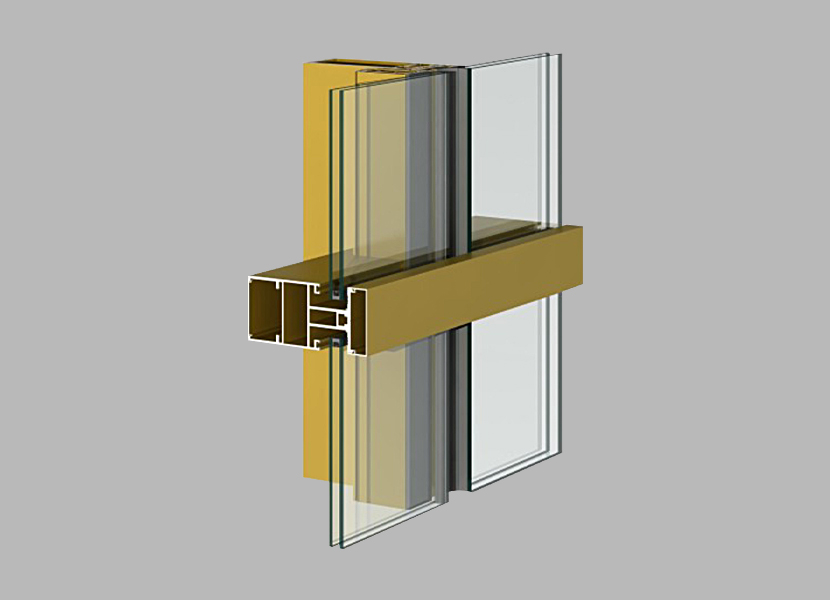

Thermal break aluminium profiles are designed to provide a thermal barrier between the interior and exterior of a building. The design of these profiles includes an insulating material, typically polyamide, that separates the interior and exterior aluminium sections. This insulating material reduces heat transfer and helps to maintain a comfortable indoor environment.

The design of thermal break aluminium profiles also includes a variety of features to enhance their performance. These features may include air chambers, which help to reduce heat transfer, and drainage channels, which prevent the accumulation of water.

Manufacturing of Thermal Break Aluminium Profiles

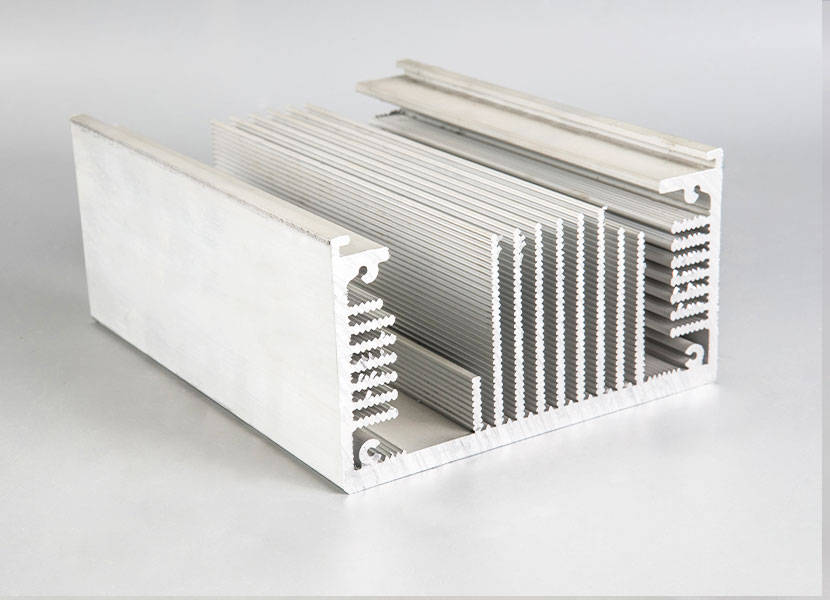

The manufacturing process of thermal break aluminium profiles is a complex and precise process that requires expertise and advanced technology. The process starts with the extrusion of the interior and exterior aluminium sections. The insulating material is then inserted between the two sections before they are joined together.

The joining process may include the use of adhesives or mechanical fasteners, depending on the design and application of the profile. The finished profiles are then subjected to rigorous quality control tests to ensure that they meet the required specifications.

Benefits of Thermal Break Aluminium Profiles

Thermal break aluminium profiles offer several benefits that make them an ideal choice for modern building construction. One of the significant benefits is their ability to reduce heat transfer, which enhances energy efficiency and reduces heating and cooling costs.

These profiles also provide excellent durability and resistance to weathering, corrosion, and impact. This durability ensures that they maintain their performance and appearance over an extended period.

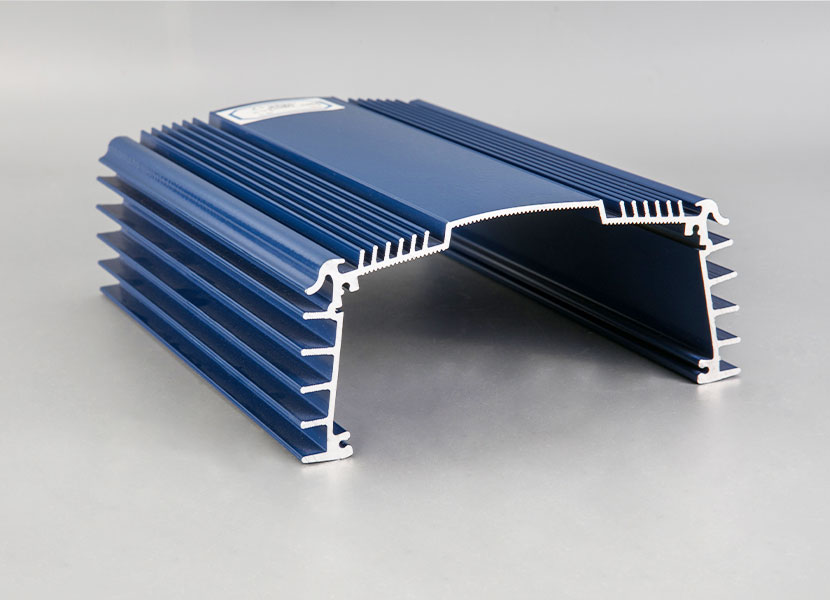

Another advantage of thermal break aluminium profiles is their versatility. They can be designed to meet a wide range of applications and requirements, from residential to commercial buildings. They are also available in various finishes, colours, and styles, making them a popular choice for architects and builders.

Conclusion

Thermal break aluminium profiles are an essential component of modern building construction, providing an efficient thermal barrier and enhancing energy efficiency. The design and manufacturing of these profiles require expertise and advanced technology to ensure that they meet the required specifications. The benefits of thermal break aluminium profiles include their ability to reduce heat transfer, durability, resistance to weathering, corrosion, and impact, as well as their versatility. With these advantages, thermal break aluminium profiles remain a popular choice for architects and builders who seek to enhance the energy efficiency and performance of their buildings.

English

English 简体中文

简体中文 España

España