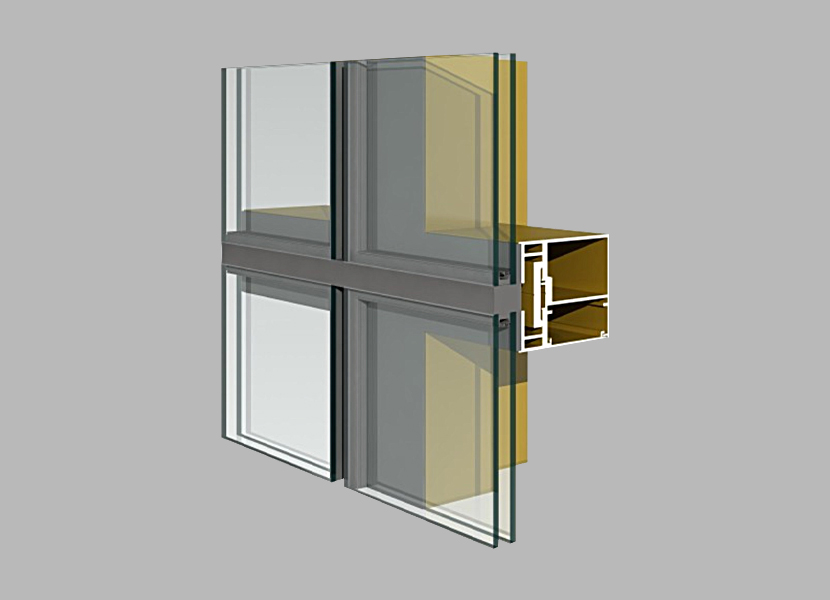

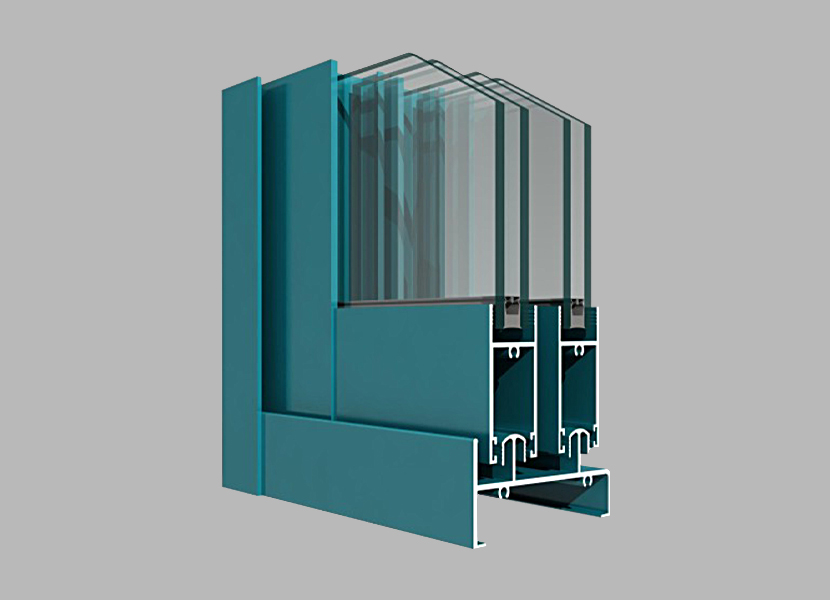

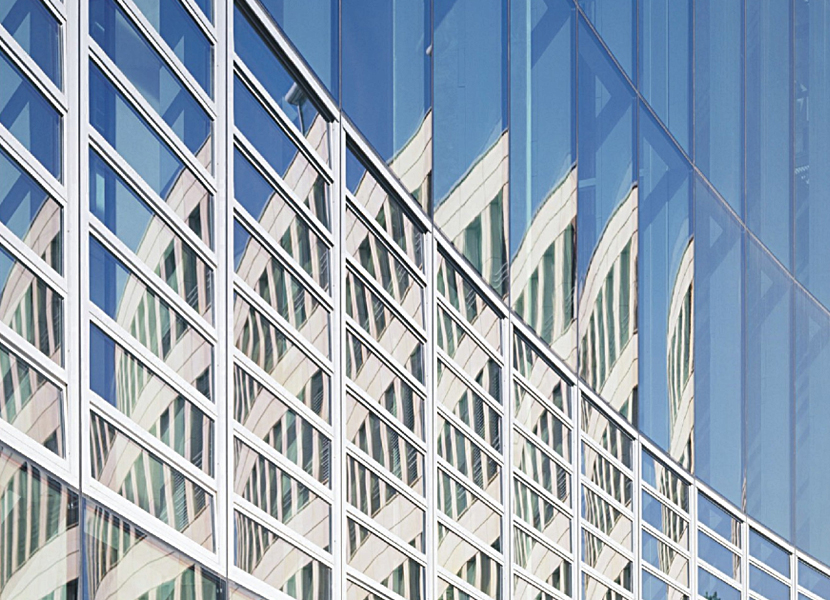

Aluminum alloy profiles are the most widely used non-ferrous metal structural materials in the industry, and have been widely used in aviation, aerospace, automobile, machinery manufacturing, shipbuilding, construction, decoration and chemical industries. With the rapid development of science and technology and industrial economy in recent years, the demand for aluminum alloy welded structural parts is increasing, and the research on the weldability of aluminum alloy is also in-depth.

Aluminum alloy profiles are the most widely used non-ferrous metal structural materials in the industry, and are used in aviation, aerospace, automobiles, machinery manufacturing, ships, construction, and decoration. And the chemical industry has been widely used. With the rapid development of science and technology and industrial economy in recent years, the demand for aluminum alloy welded structural parts is increasing, and the research on the weldability of aluminum alloy is also in-depth. The wide application of aluminum alloy has promoted the development of aluminum alloy welding technology, and the development of welding technology has expanded the application field of aluminum alloy. Therefore, the welding technology of aluminum alloy is becoming one of the research hotspots.

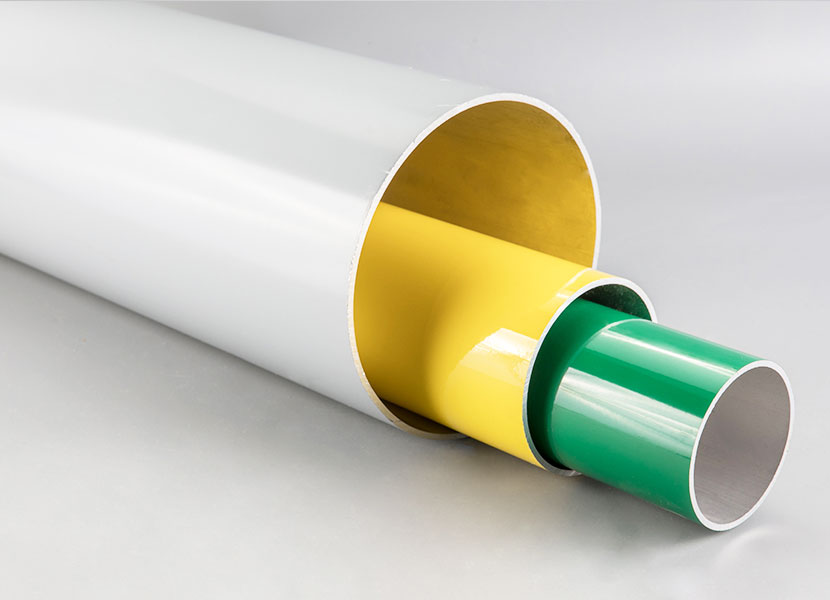

The reason for the formation of bubbles on the surface of aluminum alloy profiles: generally, the gas inside the aluminum alloy cast rod or the air involved in the extrusion process expands during extrusion and subsequent heat treatment, causing the surface of the profile to bulge and form defects.

Solution:

1. The gas content inside the aluminum alloy cast rod should be minimized.

2. The surface of the aluminum alloy cast rod is required to be clean and free of oil stains

3. Clean the extrusion barrel

4. The temperature of the aluminum alloy rod should not be too high

5. Increase the thickness of the excess pressure

6. Control the amount of lubricating oil applied to avoid excessive lubrication.

Zhejiang SUNKEY Industrial Co., Ltd. Is located in Yuyao,Ningbo city of eastern Zhejiang.As a professional Aluminium Section Manufacturers and Aluminium Section suppliers, the introduction of today's advanced production, quality control equipment, and built a set of casting, extrusion, anodizing, electrophoresis, powder coating, wooden in one of the large-scale professional aluminum manufacturing plant. We have our own foundry workshop, so we can offer good price and wholesale aluminium section. Annual production capacity of 45000 tons, the products include construction material, industrial material two series, nearly a thousand kinds of specifications, and specially designed for the customer to customize a variety of specific-type construction or industrial materials.

English

English 简体中文

简体中文 España

España