How to Choose the Right Aluminum Extrusion Profile for Your Project

Aluminum extrusion profiles are used in a wide range of industries, from construction to consumer electronics. But with so many options available, how do you choose the right one for your project? In this article, we'll explore some key factors to consider when selecting an aluminum extrusion profile.

-

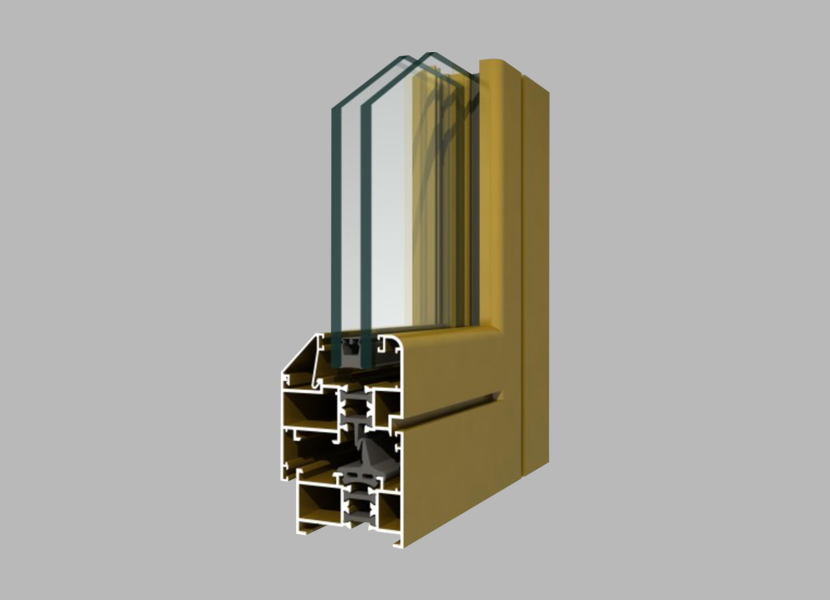

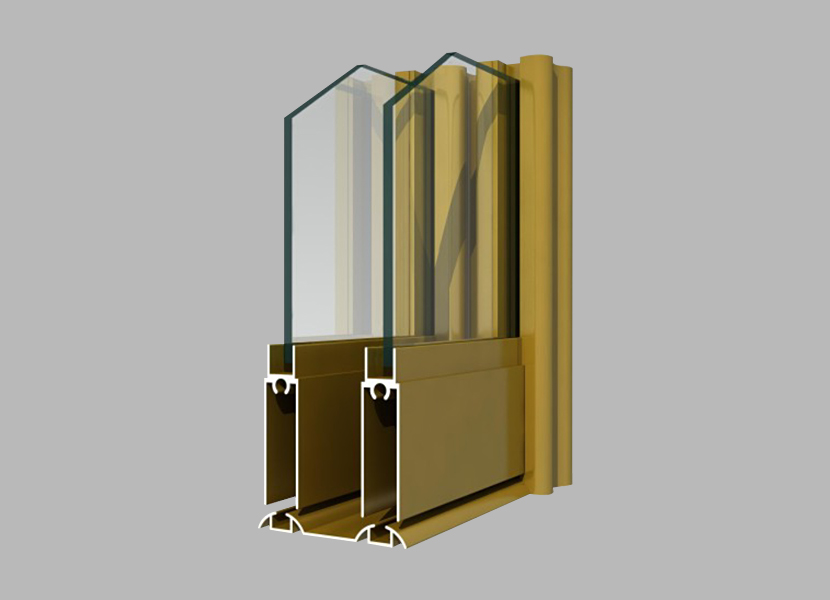

Shape and Size The first factor to consider when selecting an aluminum extrusion profile is the shape and size of the profile. Aluminum extrusion profiles can be designed in a range of shapes and sizes, so it's important to choose one that meets your specific requirements. Consider the dimensions of your project and any design constraints that may impact the shape and size of the profile.

-

Material Properties Another important factor to consider is the material properties of the aluminum extrusion profile. Different alloys offer different properties, such as strength, corrosion resistance, and thermal conductivity. Consider the specific needs of your project and choose an alloy that offers the properties you require.

-

Surface Finish The surface finish of the aluminum extrusion profile is also important. Depending on your project requirements, you may require a smooth, glossy finish or a textured, matte finish. The surface finish can also impact the profile's ability to withstand corrosion or other environmental factors.

-

Tolerance and Precision Finally, it's important to consider the tolerance and precision of the aluminum extrusion profile. This refers to the degree of accuracy that can be achieved during the extrusion process. If your project requires tight tolerances or precise dimensions, it's important to choose an extruder that can meet these requirements.

English

English 简体中文

简体中文 España

España