We all know that the cross-section of aluminum profiles is all kinds of strange, and other materials of metal can not achieve such an effect. This is related to the characteristics of aluminum profiles. The industrial aluminum profiles we usually see belong to 6 series aluminum alloys, and 6 series aluminum alloys belong to deformed aluminum alloys, which can be formed by extrusion.

The following will introduce the production process of aluminum alloy profiles:

1. Casting

(1) Ingredients: According to the specific alloy grades to be produced, calculate the addition amount of various alloy components, and reasonably match various raw materials.

(2) Smelting: The prepared raw materials are added to the melting furnace for melting according to the process requirements, and the slag and gas in the melt are effectively removed by degassing, slag removal and refining.

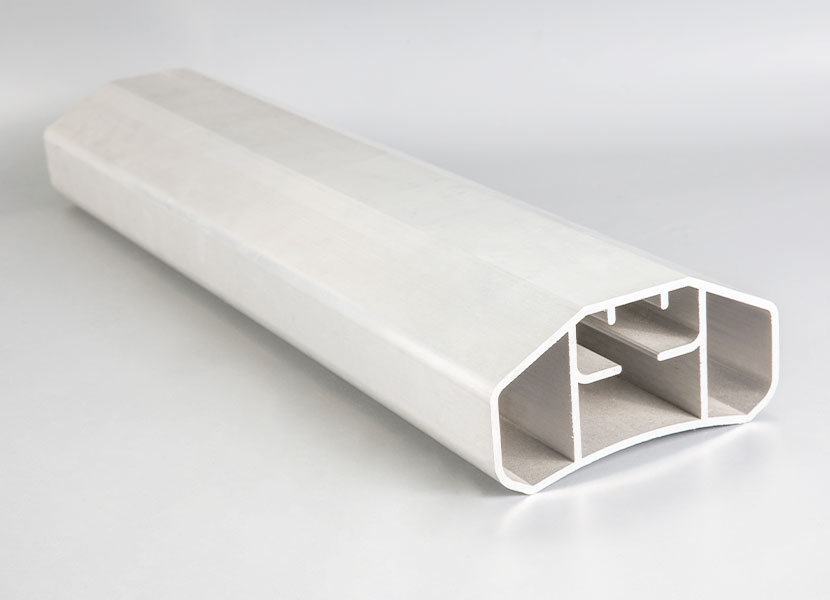

(3) Casting: Under certain casting conditions, the molten aluminum is cooled and cast into round cast rods of various specifications through a deep well casting system.

English

English 简体中文

简体中文 España

España