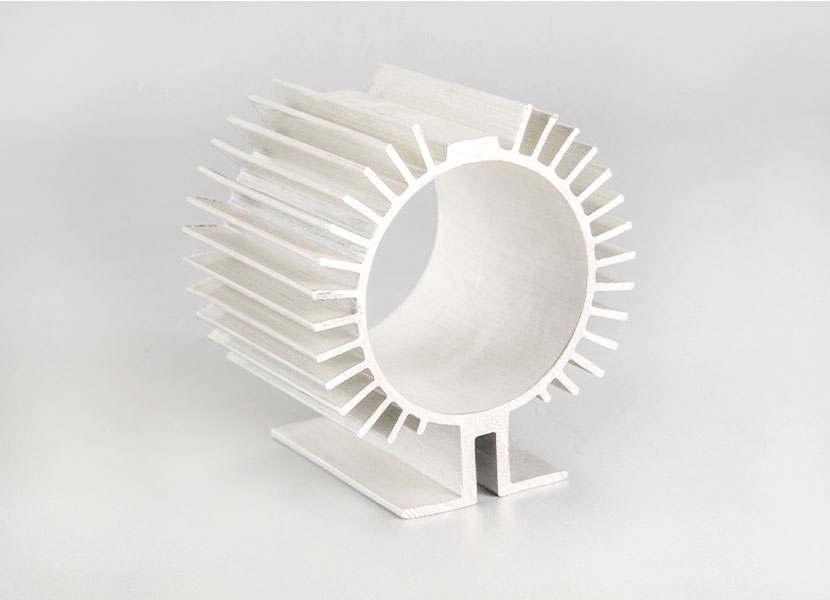

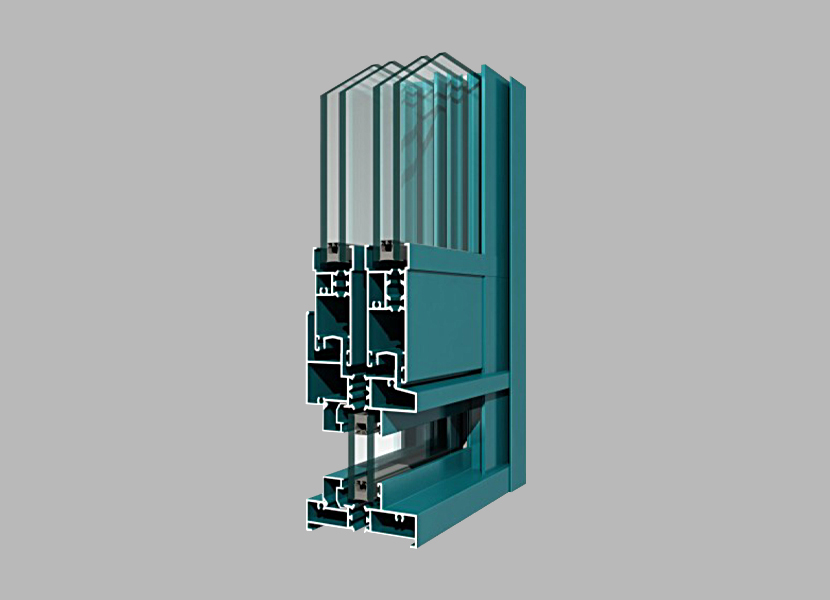

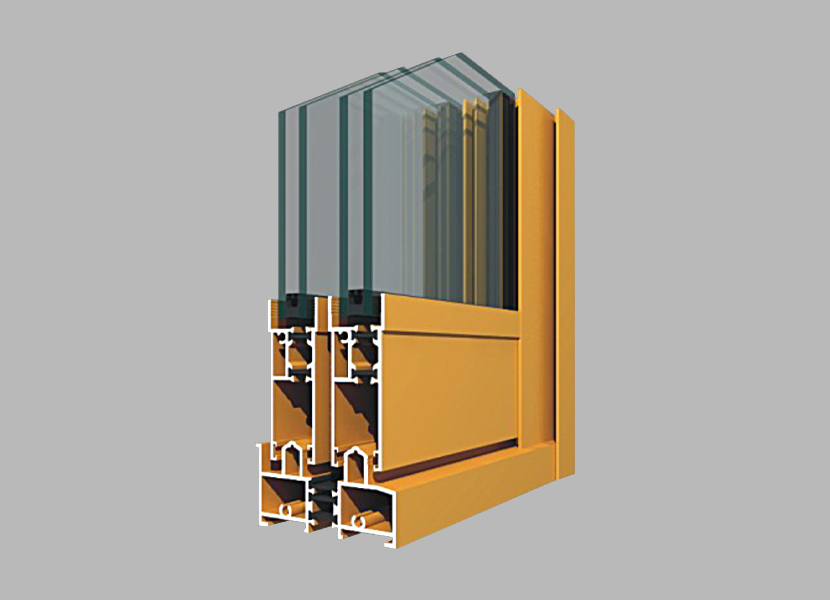

The cross-sectional shape of industrial aluminum profiles is strange and the application fields are very wide. And other metal materials can not exceed this effect. So how does it do it? First look at the main features of aluminum:

1. Extrudability, aluminum has special tensile strength, yield strength, ductility and relative work hardening rate, which determine the extrudability of aluminum.

2. Recyclability: Aluminum has extremely high recyclability. There is basically no difference between renewable aluminum and primary aluminum, and the recycling cost is low. It is a very energy-saving and environmentally friendly material.

3. Other features: Aluminum is non-toxic and does not burn.

This feature is the basis for the wide application of industrial aluminum profiles. So how are aluminum alloy profiles extruded?

1. The first is aluminum ingot forging: the aluminum ingot is heated and melted, a certain amount of alloying elements (magnesium, silicon) are added, and the casting machine is cast into round rods with different diameters.

2. Extrusion of aluminum alloy profiles: The aluminum rod is first heated to a certain temperature, exceeding the critical point of aluminum liquefaction, then cut, thermally sheared, and sent to an extruder for extrusion. cross-sectional shape. Subsequently, quenching, quenching methods include air cooling and water cooling. The air-cooled state is T5, and the water-cooled state is T6.

3. Processing of aluminum profiles after extrusion: the tractor pulls out the aluminum profiles, and the length exceeds the required length by a hot-cut saw, and the moving cooling bed moves the aluminum profiles to the straightening machine for straightening. (The aluminum alloy profile was soft when it was just extruded.) After straightening, cut it with a fixed-length saw, and load the transfer frame into the aging process.

4. Artificial aging: Put the material into the aging furnace and heat it to a certain temperature, and keep it for 2-3 hours, which can significantly improve the mechanical properties of the aluminum alloy profile, especially the hardness.

5. Surface treatment: Anodizing - The sulfuric acid solution is connected to the anode of the DC power supply to carry out a redox reaction, and then a dense and porous oxide film is formed on the surface, and then the hole is sealed, and the aluminum alloy profile will be more wear-resistant and corrosion-resistant. Electrostatic spraying—Using the Faraday effect of the current electric field, the fine particles of the powder coating are uniformly adsorbed on the surface of the material. Play the role of protecting aluminum alloy profiles.

English

English 简体中文

简体中文 España

España