Common methods of processing aluminum profiles

There are several methods of processing industrial aluminum profiles. Different processing methods of industrial aluminum profiles have different effects on the industrial aluminum profile products made later. Because of the different processing methods, the industrial aluminum profiles will be under pressure. s difference. Industrial aluminum profiles are often processed into assembly line workbenches, machine protective covers, aluminum profile frames, etc. These products play a great role in some industries. If the performance of industrial aluminum profiles changes, the impact on these industries cannot be ignored. Therefore, the processing method of industrial aluminum profiles is very important. There are 5 different types of processing methods for industrial aluminum profiles.

1. Oxidation processing: The surface of the industrial aluminum profile is treated with silver white oxidation, which is elegant, beautiful and anti-corrosion.

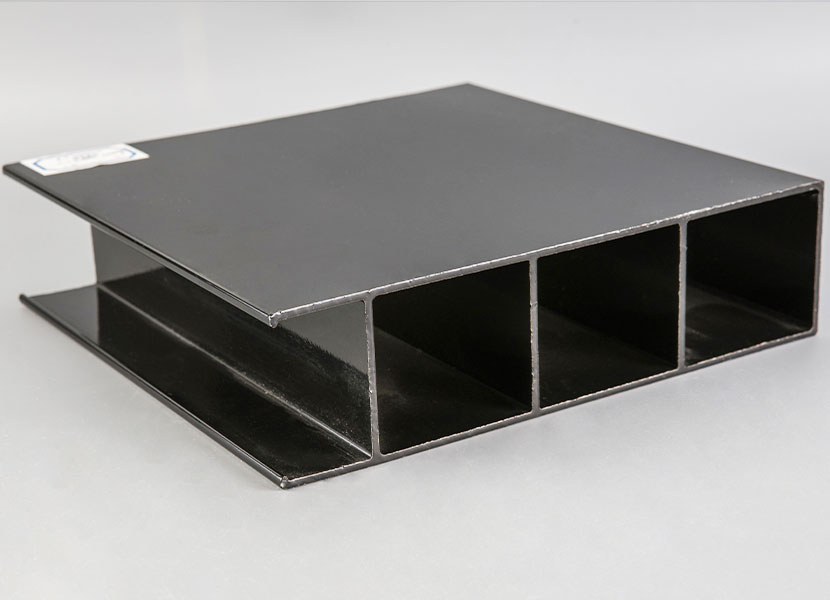

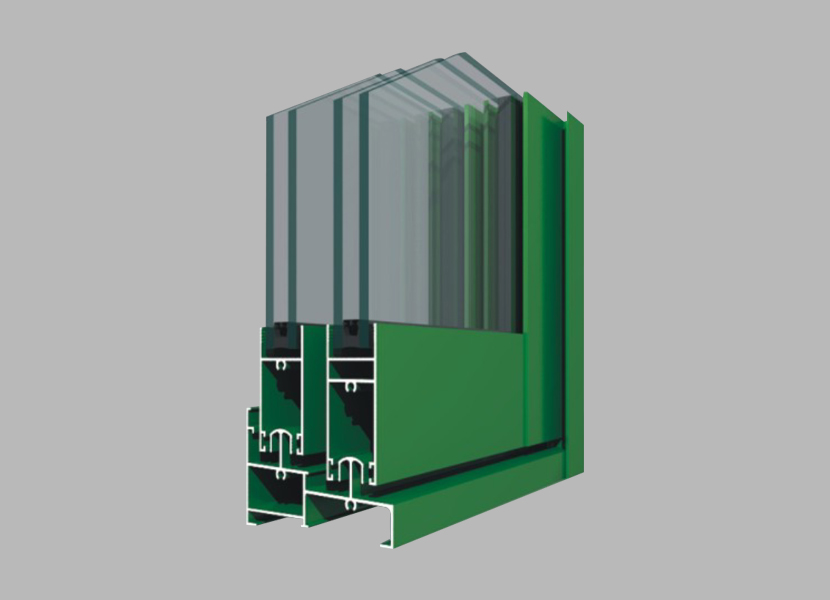

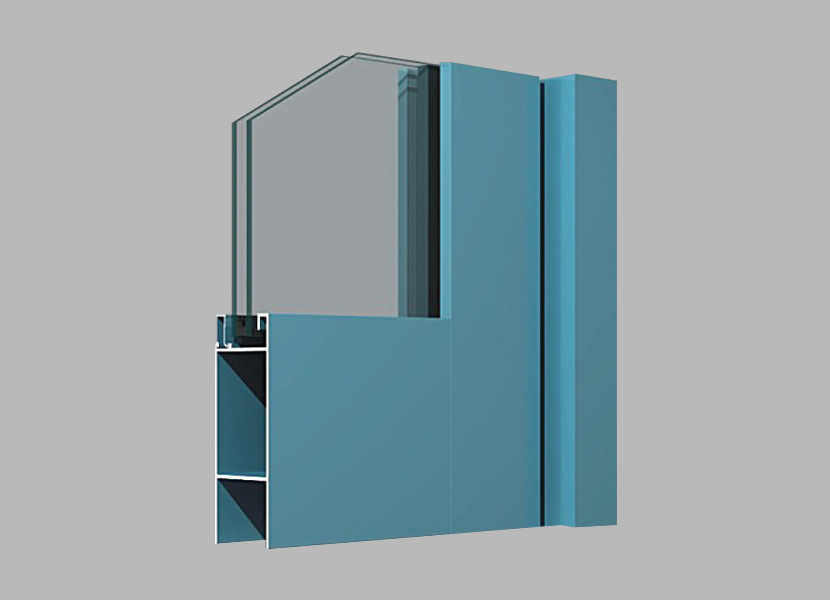

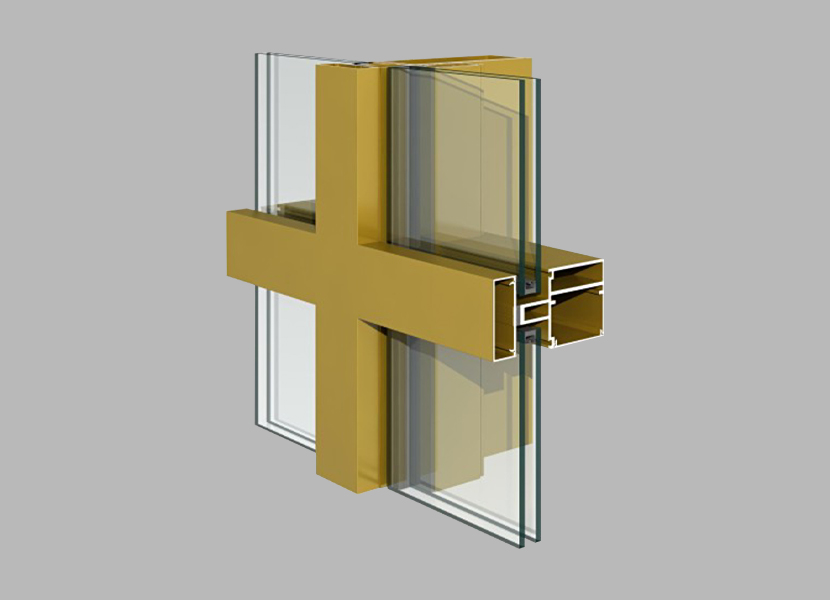

2. Extrusion: Each specification of the aluminum profile has a corresponding production mold, put the aluminum material into the mold, and form the aluminum profile required by the customer through extrusion.

3. Casting: It is similar to the early blacksmithing process seen on TV.

4. Smelting out impurities: The purity of aluminum is proportional to its performance. The higher the purity, the better the performance. Therefore, the impurity is removed by the melting furnace to increase the performance of the aluminum profile.

5. Ingredients to increase product hardness: Industrial aluminum profile is an aluminum alloy profile, including aluminum-magnesium-silicon alloy, aluminum-zinc alloy and so on. It can increase the hardness and bearing capacity of aluminum profiles.

English

English 简体中文

简体中文 España

España